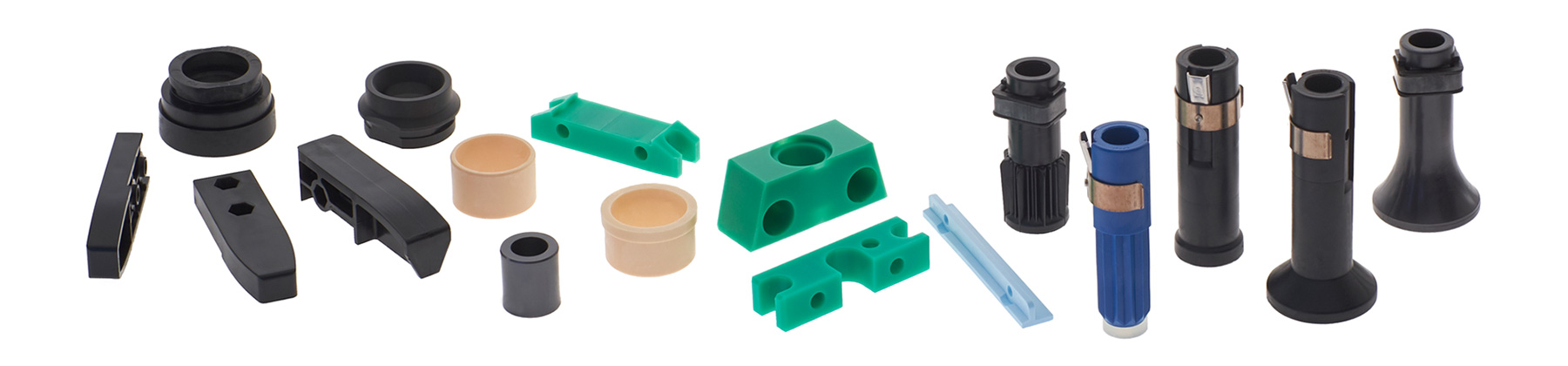

Bushings, Centering bells & further Finished parts in plastic

Finished parts in plastic in their different shapes and applications require application-specific materials. As varied as the task, so different the plastic to be used. Usually, high wear resistance, good chemical resistance as well as excellent dimensional stability and surface quality are required. However, the example of the Bushings shows that this is only half the story: Here, in particular, high impact strength, excellent vibration damping, low moisture absorption and a low coefficient of friction in dry running are required. In addition, most of them are press-in bushings, so that the corresponding tolerances are to be considered depending on the material. Every part, no matter if Bushing, Centering bell, Infeed guide finger, Slide piece, etc., require an optimum of design and material selection. Due to our decades of experience beyond others with the conditions of beverage bottling in general and our know-how of the installation situations and tasks in particular, we are able to develop and thus to deliver our Finished parts in JO® quality.

You receive detailed and up-to-date information in the following individual chapter areas and the associated PDFs: Bushings, Centering bells and further Finished parts. If you prefer to download the entire chapter “Bushings, Centering bells & further Finished parts in plastic”, you will find the corresponding PDF at the end of this product page.

OUR SERVICE

Immediate availability of Spare parts is the key to re-commission your system as soon as possible. If you moreover would like to benefit from attractive conditions,

simply contact our trained JO® team.

We are always happy to be at your disposal with competent consulting!